The process of saponification has been used for centuries to produce soap, a vital cleansing agent that is both simple and complex in its chemistry. This article explores into the intricate saponification process of making soap, breaking it down into easy-to-understand steps while providing expert insights to help you grasp the essentials. Whether you’re an enthusiast looking to create homemade soap or a chemistry student eager to understand the science, this guide will walk you through everything you need to know.

Table of Contents

Introduction to Saponification

The saponification process is the foundational chemical reaction in traditional soap making. While the concept of soap has existed since ancient times, its production has evolved significantly, rooted in centuries of knowledge and scientific discovery. Let’s explore the origins and meaning of this process.

The Historical Context of Soap Making

Soap is believed to have been first made by the ancient Babylonians around 2800 B.C. They discovered that combining animal fats with wood ashes resulted in a rudimentary cleansing substance. This discovery evolved into what we now recognize as soap, refined through the process of saponification. Over time, various cultures, including the Romans and Egyptians, developed their own soap recipes, using natural fats and plant-based oils.

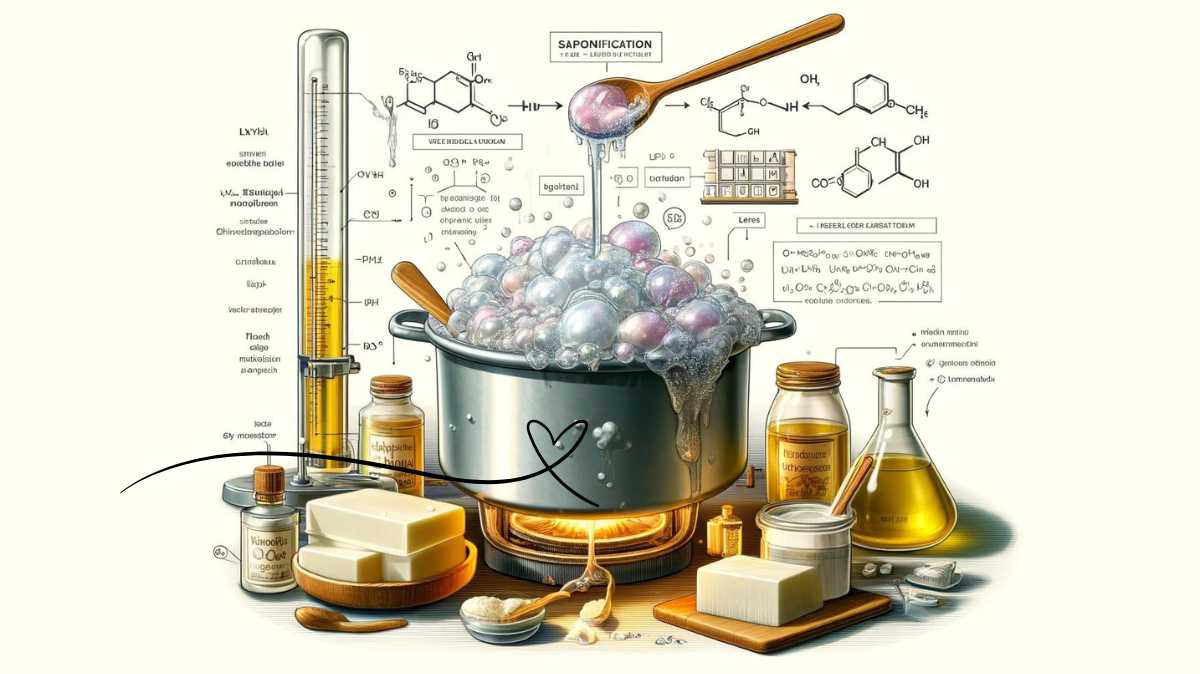

What is Saponification?

In essence, saponification is the chemical reaction between a fat (oil) and an alkali (lye), typically sodium hydroxide (NaOH) for hard soap or potassium hydroxide (KOH) for liquid soap. This reaction produces glycerol (glycerin) and soap, a salt of fatty acids.

Chemical Equation: Fat or Oil (Triglyceride) + Lye (NaOH) → Soap (Sodium Salt of Fatty Acids) + Glycerin

The Chemistry Behind Saponification

The Role of Fatty Acids and Alkali

Fats and oils consist of triglycerides, which are esters derived from three fatty acids and glycerol. When triglycerides react with an alkali, the ester bonds are broken, releasing free fatty acids, which then form soap.

The alkali, such as sodium hydroxide (NaOH), plays a critical role as it breaks down the ester bonds during hydrolysis, a key step in saponification. The choice of fat or oil affects the final soap’s properties, such as hardness, lather, and moisturizing ability.

Understanding Hydrolysis and Saponification Reactions

Hydrolysis is the process where water breaks chemical bonds. In saponification, hydrolysis occurs when triglycerides in fats or oils come into contact with lye, causing them to split into glycerol and fatty acid salts (soap).

Raw Materials for Soap Production

The type of fats, oils, and alkalis used in the saponification process directly influences the soap’s texture, color, and performance.

Common Fats and Oils Used

- Coconut Oil: Creates a hard soap with a lot of lather.

- Olive Oil: Known for its moisturizing properties.

- Palm Oil: Adds firmness to the soap.

- Shea Butter: Provides a creamy lather and skin-conditioning properties.

Types of Alkalis: Sodium Hydroxide vs. Potassium Hydroxide

- Sodium Hydroxide (NaOH): Used for making hard bar soaps.

- Potassium Hydroxide (KOH): Primarily used for making liquid soaps.

The Saponification Process Explained

Step-by-Step Breakdown

- Preparation: Measure out fats and oils based on the recipe.

- Mixing Lye: Carefully mix sodium hydroxide with water. It’s essential to add lye to water, not the other way around.

- Combining: Once the lye solution cools, combine it with oils and stir.

- Trace Stage: Continue stirring until the mixture thickens to a trace, indicating the saponification process has begun.

- Pouring: Pour the soap mixture into molds and allow it to harden.

Cold Process vs. Hot Process Soap Making

- Cold Process: After mixing, the soap is poured into molds and left to cure for 4-6 weeks. This method preserves natural glycerin, making the soap moisturizing.

- Hot Process: The soap mixture is heated to speed up saponification. The soap can be used sooner, but the texture may be less smooth.

Variables That Affect the Saponification Process

Temperature Control

Temperature plays a significant role in controlling the speed of saponification. High temperatures can accelerate the process, while lower temperatures slow it down, affecting the consistency and quality of the soap.

The Impact of Different Oils on Soap Quality

The type and quantity of oil used determine various properties of soap:

- Coconut oil adds lather and hardness.

- Olive oil contributes to mildness.

- Castor oil helps stabilize lather.

Benefits of Natural Soap Made through Saponification

Handcrafted natural soaps offer numerous benefits over commercial soaps. These include:

- Chemical-Free Skin Care: No synthetic detergents or chemicals.

- Eco-Friendly and Sustainable Soap: Environmentally friendly, biodegradable, and less polluting than synthetic alternatives.

Testing Soap for Saponification Completion

Phenolphthalein Test for pH

A pH test using phenolphthalein can determine whether the soap has fully saponified. Ideally, soap should have a neutral pH level of around 7-10.

Zap Test for Safety

The zap test involves touching the soap to your tongue. If it “zaps” like a battery, saponification is incomplete, and lye remains active.

Curing and Aging Soap

Curing is crucial to allow the water in the soap to evaporate, resulting in a harder, longer-lasting bar. Soap generally needs 4-6 weeks to cure fully, but some oils, like olive oil, require longer curing times to maximize mildness and quality.

Troubleshooting Common Saponification Problems

Soap Seizing and Gelling Issues

Soap seizing occurs when the mixture thickens too quickly. This is usually caused by using certain fragrance oils or working at high temperatures. Gelling issues arise when uneven temperatures during curing cause part of the soap to gel, resulting in a different texture.

Preventing Rancidity and DOS (Dreaded Orange Spots)

Rancidity can occur if the soap contains unsaturated fats. Adding antioxidants like Vitamin E can help prevent DOS.

Saponification in Industrial Soap Production

In commercial soap manufacturing, the saponification process is scaled to an industrial level.

Batch Process vs. Continuous Process

- Batch Process: Soap is made in large batches, allowing for easier customization.

- Continuous Process: A more efficient method used for large-scale production, where the ingredients flow continuously through the system.

Environmental Impact of Soap Production

Soap is biodegradable and far less harmful to the environment than synthetic detergents. However, the cultivation of palm oil, a common soap ingredient, can have negative environmental impacts unless sourced sustainably.

How Soap Affects Aquatic Life

Most natural soaps degrade quickly in water, minimizing their impact on aquatic life. However, synthetic additives can linger and cause harm.

Safety Precautions in Soap Making

Handling Sodium Hydroxide Safely

Sodium hydroxide is highly caustic and must be handled with care. Always wear gloves and goggles when working with lye to prevent chemical burns.

Personal Protective Equipment (PPE) in Soap Making

It is critical to use protective gear, such as long sleeves, safety glasses, and gloves, to protect against lye exposure.

Frequently Asked Questions

What is the Difference Between Soap and Detergent?

Soaps are made through saponification and are natural products, while detergents are synthetic surfactants made from petrochemicals.

Can Soap Be Made Without Lye?

No, soap cannot be made without lye. However, finished soap does not contain active lye, as it reacts completely with the oils during saponification.

How Do I Know When My Soap is Ready?

Soap is ready when it has fully cured for 4-6 weeks and passes the pH and zap tests.

Why Does Soap Need to Cure?

Curing allows the water to evaporate, making the soap harder and longer-lasting. It also ensures that saponification is complete.

How Long Does the Saponification Process Take?

The actual reaction may take a few hours, but the soap must cure for weeks to achieve optimal quality.

Final Thoughts

The saponification process of making soap is both an ancient art and a science, combining simple ingredients to create a product that is essential to everyday life. Whether you are crafting soap at home or exploring it on a commercial level, understanding the nuances of saponification can help produce high-quality, natural soap that benefits both you and the environment.

Author

An aspiring business leader, I am working towards my dream of graduating from Stanford University with a degree in Business Management. Passionate about sharing knowledge, I strive to empower others through education and collaborative learning.

View all posts